Planning & Commission Brief

Build Log 001: Planning Phase and Commission Brief

Date: December 15, 2024

Phase: Project Planning and Research

Time Spent: ~8 hours

Status: Planning Complete

The Commission

It started casually over a relaxing evening with my son and his family in November 2024. Fresh from completing the English Country Garden, I was feeling confident - perhaps overconfident.

“So do you have anything that I can build for you?” I asked jokingly.

“Yes!” came the immediate response. “Can you build our new caravan and car on a campsite next to a river?”

And just like that, I had a commission.

Client Requirements:

- Eriba Triton caravan (their actual model)

- VW Golf R Estate in red (their actual car)

- Two figures (my son and daughter-in-law)

- Tilly (their beloved dog)

- Campsite setting near a river

- Welsh countryside scenery

- Must fit on 25cm × 25cm base (shelf space constraint)

Reality Check: What I’d Never Done Before

As the excitement settled, reality set in. This commission required skills I didn’t have:

Vehicle Modeling: Zero experience

- Never built a miniature car or caravan

- No idea how to achieve smooth automotive curves

- Uncertain about materials and techniques

Portrait Figures: Previous failures

- My figure work was poor and not recognizable

- Never successfully sculpted specific people

- Concerned about client disappointment

Animals: Complete unknown

- Never attempted a miniature dog

- No reference for techniques

- Tilly needed to be recognizable

Water Effects: Previous attempt unsatisfactory

- Log Cabin river was disappointing

- Needed to research better techniques

- Resin work was new territory

Despite these challenges, I accepted the commission. The only way to improve is to push beyond comfort zones.

Scale Determination

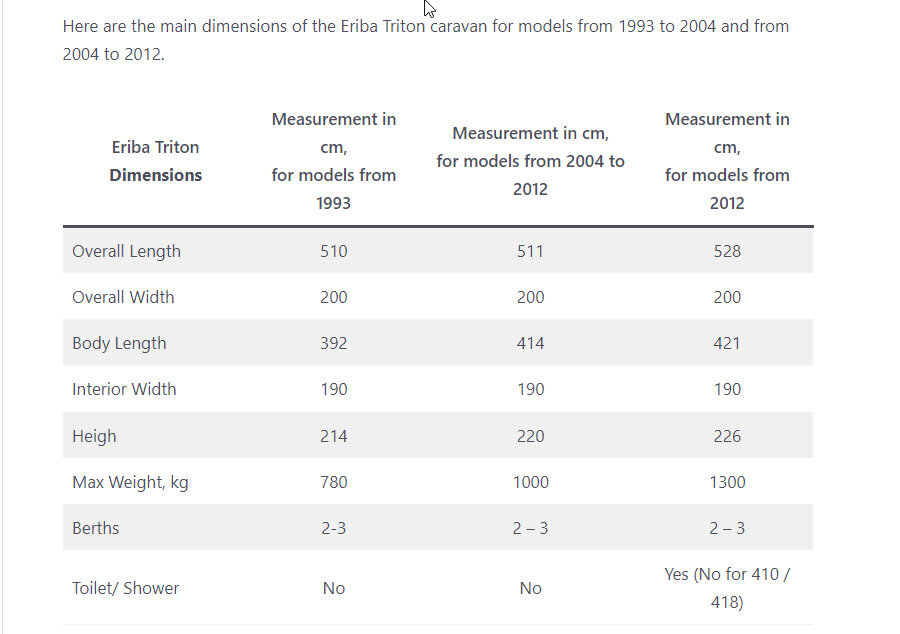

With a fixed 25cm × 25cm base (dictated by available shelf space), I needed to work backwards from the caravan dimensions to determine the scale.

Research Phase

I collected extensive reference material:

- Manufacturer Specs: Official Eriba Triton dimensions

- Online Photos: Multiple angles and detail shots

- Other Models: Found one example of someone’s scratch-built Eriba

- Site Visit: Photographed the actual caravan and car on location

Scale Calculations

Working from the Eriba Triton’s actual dimensions, everything calculated to 1:42 scale.

Caravan Dimensions (mm):

| Element | Model | Actual | Ratio |

|---|---|---|---|

| Body Length | 100mm | 4210mm | 1:42.1 |

| Overall Length | 125mm | 5280mm | 1:42.2 |

| Width | 48mm | 2000mm | 1:41.7 |

| Height | 54mm | 2260mm | 1:41.9 |

The slight variations average out to 1:42 - close enough for visual accuracy.

Related Elements at 1:42:

| Item | Model Size | Real Size | Notes |

|---|---|---|---|

| Base | 250mm | 10.5m | Entire scene footprint |

| Man | 48mm | 2.0m | 6’6” figure |

| Woman | 40mm | 1.7m | 5’7” figure |

| Dog (Tilly) | 12mm | 500mm | Medium-sized dog |

| Car | 90mm | 3.8m | VW Golf Estate |

| Large Tree | 143mm | 6.0m | Background tree |

| River Width | 71mm | 3.0m | Backdrop river |

| Large Plant | 48mm | 2.0m | Tall shrub |

| Flower Head | 1mm | 40mm | Individual bloom |

This mathematical foundation gave me confidence - if I got the proportions right on paper, everything would look correct together.

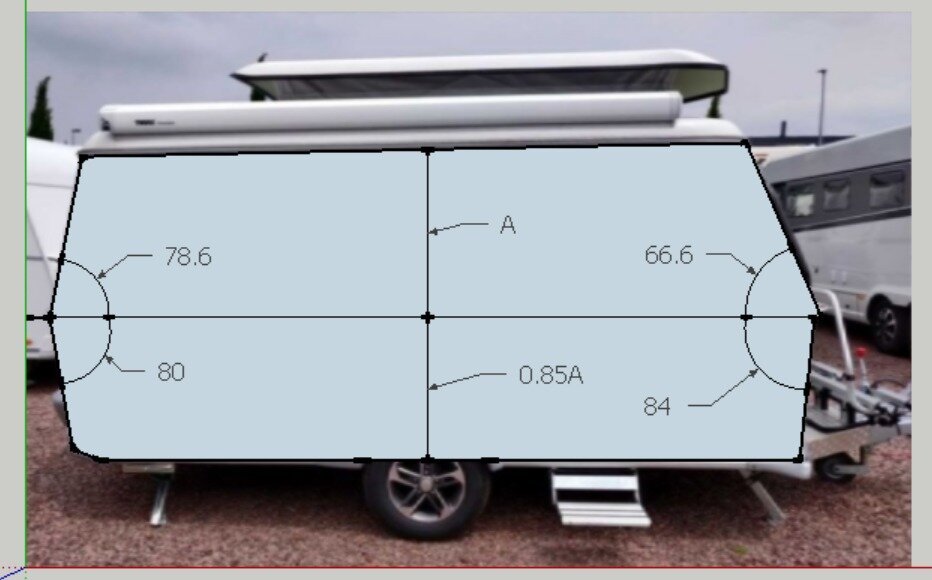

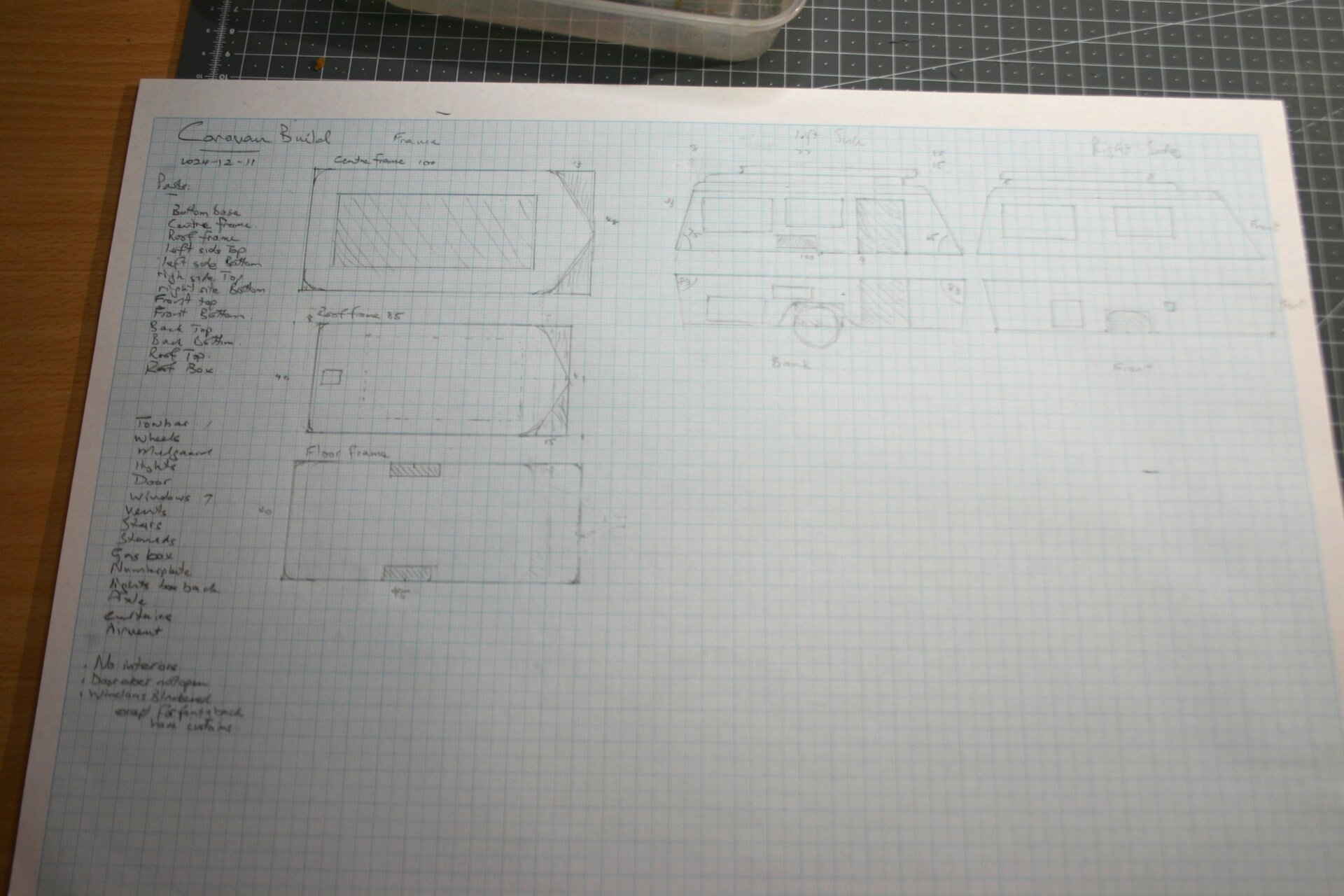

Creating Working Plans

Without formal architectural drawing skills, I work “to the eye” - measuring and fitting as I build. But for this commission, I needed more structure:

Planning Documents Created:

- Scale conversion table for all elements

- Cutting sheet for caravan body layers

- Reference photo collection organized by component

- Materials list for each build phase

- Angle calculations from side-view photos

The cutting sheet became my blueprint. Even though I knew I’d adjust during construction, having these dimensions calculated in advance prevented major errors.

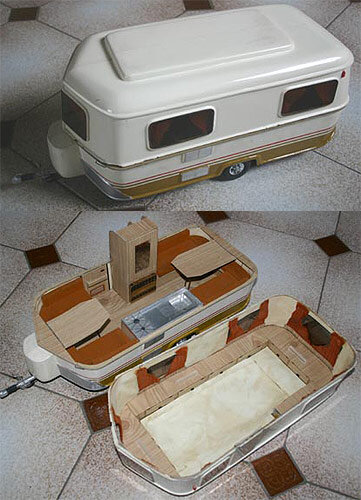

Research - The Eriba Challenge

Research Findings:

- No kits available at any scale for Eriba caravans

- No building plans for model makers

- Very few examples of scratch-built Eribas

- One successful build found online (pictured above)

The one example I found was crucial - it proved someone else had successfully scratch-built an Eriba. If they could do it, so could I.

Key Details to Capture:

- Distinctive curved body shape (Eriba’s signature “egg” profile)

- Large curved windows (particularly challenging front nose windows)

- Characteristic mudguards

- Jockey wheel and hitch

- Wheel design and proportions

- Rear bumper and lights

Research - The VW Golf Estate

Car Challenge:

- No model kits at 1:42 scale for Golf Estate

- Purchased 1:43 VW Golf sedan as sizing reference

- Needed to modify proportions for estate body style

- Required understanding of automotive curves and details

Key Details to Capture:

- Estate roofline (longer than sedan)

- Rear hatch design

- Red paint finish

- Actual license plate number (for personal touch)

- Wheel design

- Light clusters

- Window proportions

Build Strategy Decision

With all research complete, I faced a critical decision: what to build first?

Decision: Build the caravan first.

Reasoning:

- Most technically challenging component

- If I couldn’t successfully build the caravan, there was no point continuing

- Would establish whether my techniques could achieve the required quality

- Learning curve on caravan would inform car build

- Failure early is better than failure late

This was a risk-management decision. Better to discover my limitations early than invest 50+ hours only to fail on the centerpiece component.

Materials Planning

Caravan Construction:

- Balsa wood (body layers and roof)

- Milliput two-part epoxy putty (body shaping)

- 1.5mm aluminum wire (window frames)

- 0.5mm aluminum wire (inner window detail)

- Transparent plastic (window panes)

- Tissue paper (curtains)

- Bamboo (wheel construction)

- Paper (tire treads)

- Hot glue (detail work)

Car Construction:

- Air-dry clay (body shaping) - new material to try

- Balsa wood (internal structure)

- Plastic sheet (windows)

- Hot glue (lights)

- Paint (automotive red finish)

Figures:

- Wire (armatures)

- Air-dry clay - easier to work than epoxy putty

- Wood (Tilly the dog)

- Paint (flesh tones and clothing)

Scenery:

- Static grass - new tool to try

- Wire (trees and plant armatures)

- Paper (leaves and petals)

- Sawdust (tree foliage)

- Clear casting resin (river) - improved technique needed

- Paint and natural materials

Mental Preparation

This commission represented several firsts:

- Working to someone else’s specifications

- Fixed deadline (general expectation, not hard date)

- Subjects that needed to be recognizable (their actual caravan and car)

- Space constraints not of my choosing

- Potential for client disappointment

Mindset Adjustments Needed:

- “Good enough” wouldn’t be good enough

- Multiple rework cycles must be accepted

- Research before action (less trial-and-error)

- Document process for problem-solving

- Manage expectations (figures might not be portrait-quality)

I discussed with my son that the figures would be stylized rather than exact portraits - managing this expectation early was important.

Timeline Estimate

Initial Planning: 7 months seemed reasonable

Breakdown:

- Caravan: 2-3 weeks

- Car: 2-3 weeks

- Figures: 1 week

- Scenery: 2 weeks

- Final assembly: 1 week

- Buffer for rework: 3-4 weeks

Reality: This was reasonably accurate - completed July 2025 (7 months)

Key Decisions Made

- Scale: 1:42 (driven by caravan dimensions and base constraint)

- Build Order: Caravan first (make-or-break component)

- Materials: Willing to try new materials (air-dry clay, static grass, resin)

- Simplifications: No awning, no extensive campsite, focus on core elements

- Quality Bar: Multiple rework cycles acceptable to achieve client satisfaction

Next Steps

With planning complete, the next phase: attempting the Eriba Triton caravan.

This was the moment of truth - could I actually build a recognizable miniature vehicle from scratch?

Coming in Build Log 002: Caravan Construction - Three layers of balsa, countless hours with epoxy putty, and the challenge of those curved Eriba windows.

Reflection

Planning a commissioned piece feels different from planning personal projects. There’s a weight of responsibility - capturing someone else’s memories, meeting their expectations, working within their constraints.

But there’s also motivation: the desire to deliver something that brings joy, captures a moment in time, preserves a memory.

The research phase revealed both challenges and possibilities. Every “this seems impossible” moment was balanced by “but someone else did it, so I can too.”

Time to stop planning and start building.

Materials Purchased This Phase:

- Milliput epoxy putty (2 packs)

- Air-dry clay (1kg)

- Clear casting resin kit

- Static grass applicator + grass fibers

- Aluminum wire (various gauges)

- Transparent plastic sheets

- Reference car model (1:43 VW Golf)

Time Spent: ~8 hours (research, calculations, planning)

Cost So Far: ~£45

Confidence Level: Cautiously optimistic

Next Build Log: 002 - Caravan Construction

Have questions or feedback about this project? I'd love to hear from you.

Modelling4Comfort

Modelling4Comfort