Sea Rescue - Constructing the Fishing Trawler

Current Build Stage

Phase: Vessel Construction - Fishing Trawler

Focus: Building the small coastal fishing boat in distress that will be the subject of the rescue operation

Build Approach

Based on the research findings, the second option will be used by adapting plans and convert them to scale cutting sheets for the boat.

I’m constructing a small coastal fishing trawler approximately 13cm in length at 1:84 scale (representing a 11.4m vessel). This boat will appear weathered and in distress, listing slightly to add drama to the rescue scene.

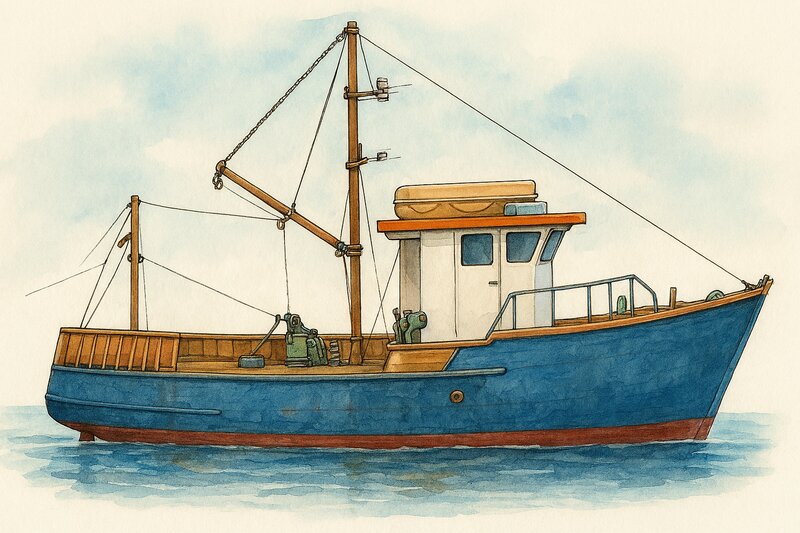

illustrative trawler from the plans

illustrative trawler from the plans

The main construction will be a mixture of wood strips cut from bayleaf and apple trees, balsawood and bamboo.

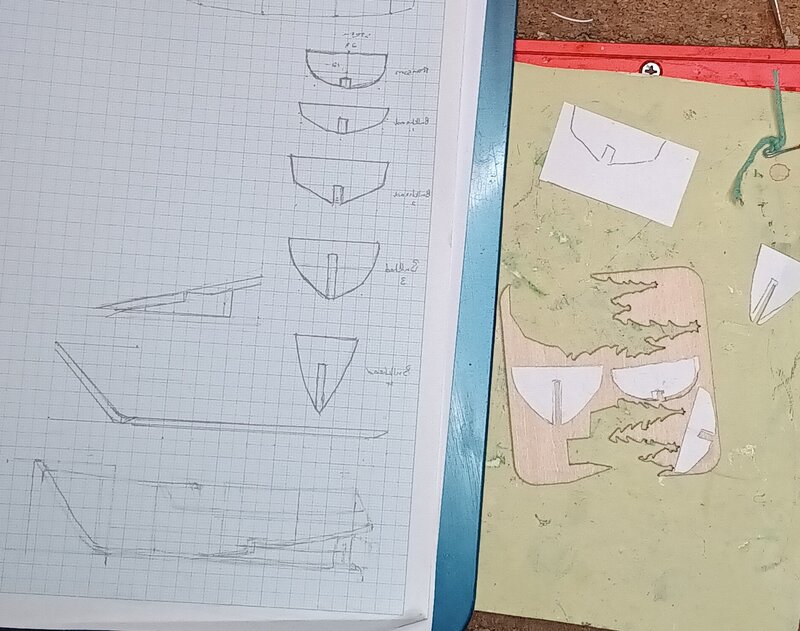

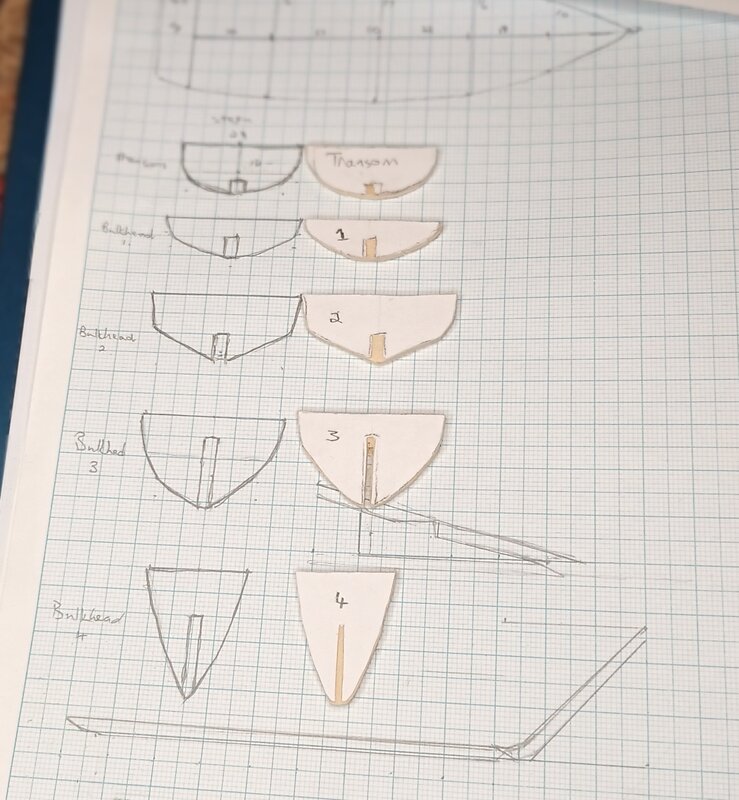

Plan conversion

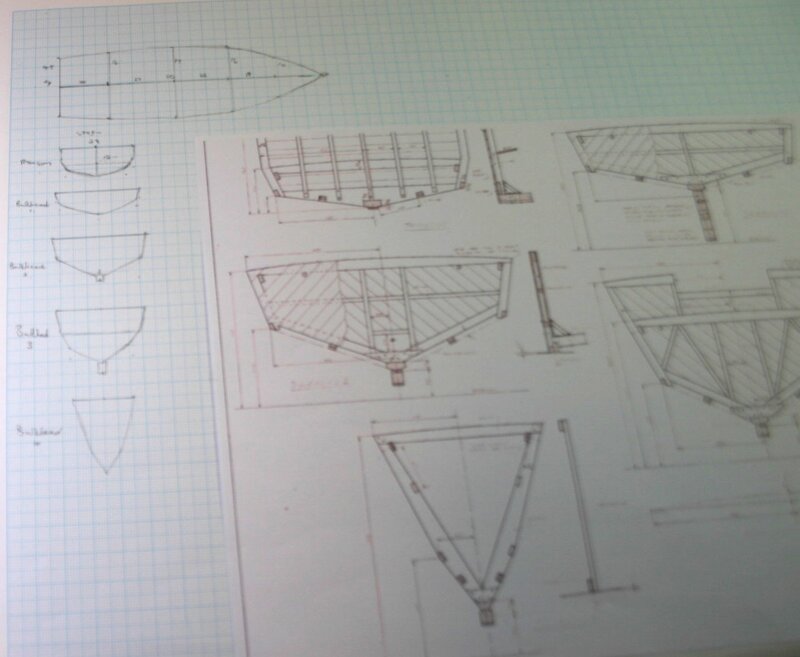

The trawler plans are printed and then partly hand drawn to scale on graphical paper focussing on drawing all the parts to be manufactured.

converting the plans to a cutting sheet

converting the plans to a cutting sheet

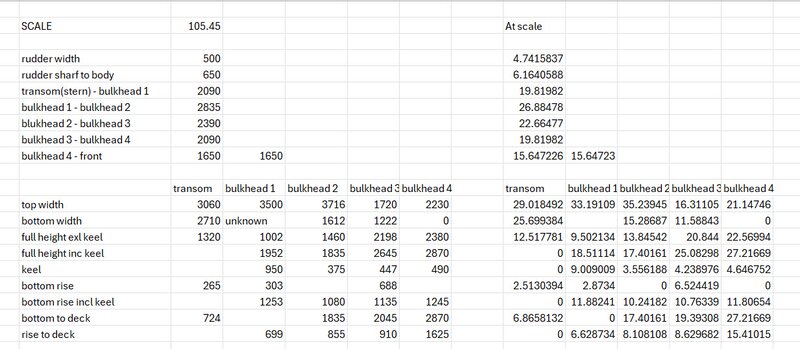

All the measurements are lifted from the plans and converted in tables to the scale.

converting the main hull measurements from the plans to scale

converting the main hull measurements from the plans to scale

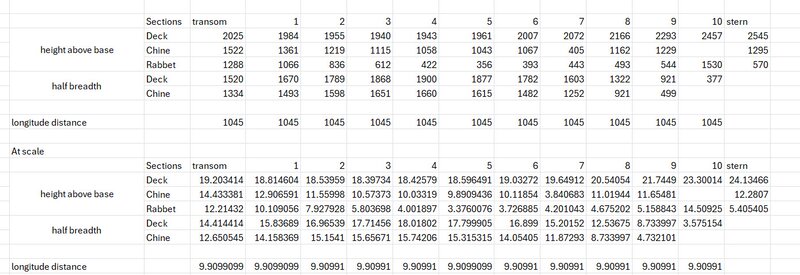

converting the segments of the hull measurements from the plans to scale

converting the segments of the hull measurements from the plans to scale

Parts list

Fishing Trawler Parts (Scale 1:75, ~10 cm length)

Hull & Superstructure

- Hull: Main body of the vessel. Approx. Size: 10 cm long, 3 cm beam, 2.5 cm depth. Material: Wood

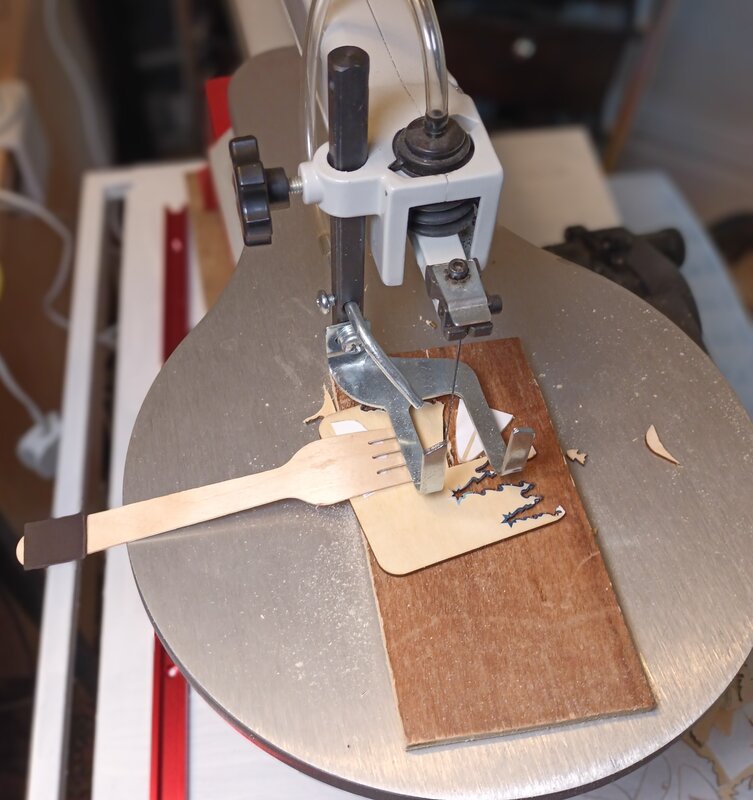

The Bullheads are cut out of left over three ply sheets. First the items are traced to paper, and then cut out, making sure the two parts of each item is identical. Then glueing it to the three ply and cutting it out with the scroll saw.

paper templates of cutting sheet

paper templates of cutting sheet

cutting the small pieces on the scroll saw using wooden fork as fingers to hold pieces down

cutting the small pieces on the scroll saw using wooden fork as fingers to hold pieces down

Bullheads after cutting

Bullheads after cutting

- Keel

The keel is measured and cut from strips of wood. The wood is planed to a consistent thickness of 5mm, sanded and then cut with a then cut to size with the correct angles with a miter shear.

Strips of wood prepared in different sizes from apple tree and bayleaf tree

Strips of wood prepared in different sizes from apple tree and bayleaf tree

Using the cutting plan to get the lenghts and angles correct, the keel strips are glued together

keel built up from individual strips

keel built up from individual strips

- Fitting the bullheads and deck

Testing the fit of the bullheads proved to be quite tricky. It keeps on falling apart.

bullhead levels tested

bullhead levels tested

- Deck

Using the cutting template the main deck is cut out of Balsawood. The three bullheads then glued to the bottom, using side strips to increase to glue surface

bullheads fitted to bottom of deck.

bullheads fitted to bottom of deck.

- planking

Making and fitting the sides of the hull and the bulwarks proved to be very tricky. With the partial deck in place, the bulwarks could be visualised to get the angles and curves right. This was initially done by using paper to form and visual it. I then decided to use thin balsawood that allow bending the curve, the paper template was glued onto the balsawood to provide more elasticity and prevent it from breaking. The top railing of the bulwark was then cut out of wood slates from an old blind and glued to the bulwark.

bulwark pict

The planking for the hull presented the next main challenge. The hull has some sharp twists and beds to accomplish, and planking from strips of wood proved to be too brittle. After several experiments with different types of cuts and wood strips, decided to use heavy paper, paint and seal it with a mixture of PVA glue and paint on both sides, and then cut it into strips. These strips were then curved along the bullheads to form the outer shell of the hull.

fitting the sides

refer to techniques:

- Bulwarks & Gunwale: Raised sides for safety. Approx. Height: 3–4 mm above deck.

- Deck: Working surface. Fits hull interior.

- Wheelhouse / Bridge: Navigation and control. Approx. Size: 2 cm × 1.5 cm × 1.8 cm. Includes windows, roof hatch, door.

- Cabin Roof Details: Vent pipes, lifebuoy, radar dome, exhaust stack.

Masts & Rigging

- Foremast & Aft Mast: Support for trawl gear and lights. Approx. Height: 6–7 cm. Material: Brass rod or toothpicks.

- Booms & Spreaders: Hold trawl doors and net rigging. Approx. Length: 3–4 cm.

- Rigging Lines: Fine thread or fishing line.

Deck Gear

- Winches (Main Trawl Winch): Haul nets and warps. Approx. Size: 1 cm × 0.8 cm cylinder.

- Capstan / Windlass: Anchor handling.

- Towing Pins & Rollers: Guide cables.

- Net Drums: Store trawl nets. Approx. Size: 0.8 cm diameter.

Fishing Gear

- Trawl Doors (Otter Boards): Keep net open. Approx. Size: 1 cm × 0.5 cm each.

- Trawl Net (Codend): Catch fish. Material: Fine mesh or gauze.

- Floats & Weights: Net buoyancy and sinking. Material: Beads or wire.

Propulsion & Steering

- Propeller: Approx. Diameter: 0.8 cm.

- Rudder: Approx. Height: 1 cm.

- Shaft Housing: Brass tube or styrene.

Safety & Navigation

- Navigation Lights: Painted beads or styrene.

- Radar Mast & Antenna.

- Lifebuoys: Tiny rings from wire or card.

- Anchor: Approx. Size: 0.5 cm.

Crew Details

- Figures: Scaled to 1:75, ~2.4 cm tall.

Work Completed

Hull Construction

The hull forms the foundation of the trawler and needs to convey both the working nature of the vessel and its current distress:

- Hull Shape: Carved from basswood using the traditional boat-building approach

- Method: Roughed out overall shape with craft knife, refined with sanding blocks

- Design: Characteristic fishing boat lines - wider beam for stability, modest freeboard

- Distress Position: Built with slight list angle to suggest trouble

Superstructure & Wheelhouse

Small fishing trawlers have a distinctive wheelhouse forward of the working deck:

- Wheelhouse Construction: Built from styrene sheet (0.5mm and 1mm)

- Windows: Cut openings for wheelhouse windows, will add clear plastic later

- Roof: Slightly angled roof typical of working vessels

- Details: Door opening on port side

Deck Features

The working deck needs to convey the vessel’s fishing purpose:

- Main Deck: Balsa sheet planking with scribed plank lines

- Gunwales: Strip wood reinforcement along deck edges

- Hatches: Small hatch covers scratch-built from card and strip wood

- Bulwarks: Low side walls built up from basswood strips

Equipment & Details

Working vessels accumulate equipment and gear:

- Mast: Brass rod for a simple mast with derrick/boom arrangement

- Winch: Scratch-built winch housing from styrene scraps

- Cleats & Fittings: Small cleats formed from brass wire

- Rail Details: Safety rails from fine brass wire

Techniques Used

Carved Basswood Hull

Working with basswood for hull construction:

- Draw waterline and profile views on block

- Rough cut with craft knife, working from centerline outward

- Sand to smooth curves using progressively finer grades

- Seal with diluted PVA before painting

Scribed Plank Lines

Creating realistic deck planking:

- Rule pencil lines for plank positions

- Score along ruler with blunt needle or scribing tool

- Don’t press too deep - subtle is realistic

- Slight irregularities add character

Scratch-Built Wheelhouse

Building small structures from styrene:

- Cut pieces slightly oversize

- Test fit before gluing

- Use liquid poly cement for strong bonds

- Square up with set square during assembly

Challenges & Solutions

Challenge 1: Scale Accuracy at 1:72

The Problem:

At 1:72 scale, the trawler is only 9-10cm long. Details must be simplified while remaining recognizable. Too much detail looks busy; too little looks toy-like.

The Solution:

Focus on key characteristic features - wheelhouse shape, deck layout, mast position. Suggest detail rather than attempting every fitting. Paint and weathering will add visual complexity.

Lessons Learned:

Working at this scale requires restraint. “Suggestion” is more effective than precise reproduction.

Challenge 2: Hull Shaping Symmetry

The Problem:

Carving a symmetrical hull freehand is challenging. One side becoming heavier than the other throws off the look.

The Solution:

Frequent measuring with calipers. Mark centerline clearly. Sand both sides equally, checking frequently. Hold hull up to light to spot asymmetries.

Lessons Learned:

Patience with hull shaping pays off. Rush the sanding and you end up with problems that show even after painting.

Challenge 3: Tiny Wheelhouse Windows

The Problem:

Cutting clean window openings in 0.5mm styrene at this scale without cracking or warping the material.

The Solution:

Score outline heavily with new blade. Make multiple passes rather than trying to cut through in one go. Support material from behind. Use sharp punch for corners if available.

Lessons Learned:

Sharp blades are essential for small-scale work. Dull blades tear rather than cut.

Materials & Tools Used

Materials

- Basswood block (2cm x 3cm x 10cm for hull carving)

- Styrene sheet (0.5mm and 1mm for superstructure)

- Balsa sheet (1mm for decking)

- Basswood strip (various sizes for details)

- Brass rod (1mm for mast)

- Brass wire (0.3mm for rails and rigging)

- Liquid poly cement for styrene

- PVA glue for wood

- CA glue for brass fittings

Tools

- Craft knife with #11 blades (fresh blades essential)

- Sanding blocks (coarse, medium, fine)

- Metal ruler and set square

- Small files for detail work

- Pin vise and drill bits for rigging points

- Calipers for symmetry checks

- Scribing tool for plank lines

Next Steps

The fishing trawler hull and superstructure are now complete. Next stages:

- Painting: Base coat and color scheme appropriate to working fishing vessel

- Weathering: Heavy weathering to show hard-worked vessel - rust, salt spray, worn paint

- Rigging: Add fishing gear, ropes, nets (suggested rather than detailed)

- Final Details: Navigation lights, name board, registration numbers

- Crew Figures: Small figures to show scale and add life

- Distress Elements: Visual indicators of the vessel’s trouble (listing, damage suggestions)

Once the trawler is complete, it will be positioned on the diorama base to establish the rescue scene composition before constructing the RNLI rescue boat.

Time Investment

This Session: Approximately 8-10 hours

Breakdown:

- Hull carving and shaping: 4 hours

- Wheelhouse construction: 2 hours

- Deck and details: 2 hours

- Equipment and fittings: 2 hours

Total Project Time So Far: 12-15 hours (including planning phase)

Status: Fishing trawler hull and basic structure complete, ready for painting and weathering

Next Log: Construction of the RNLI B-class Atlantic 85 rescue boat

Estimated Next Update: Early January 2026

Have questions or feedback about this project? I'd love to hear from you.

Modelling4Comfort

Modelling4Comfort