Ss Great Britain - Build Log : Decking

With the hull covered with its steel skin, I would turn my attention to the different structures on the deck. I started off by experimenting with crafting the hatches as illustrated in this reference photo.

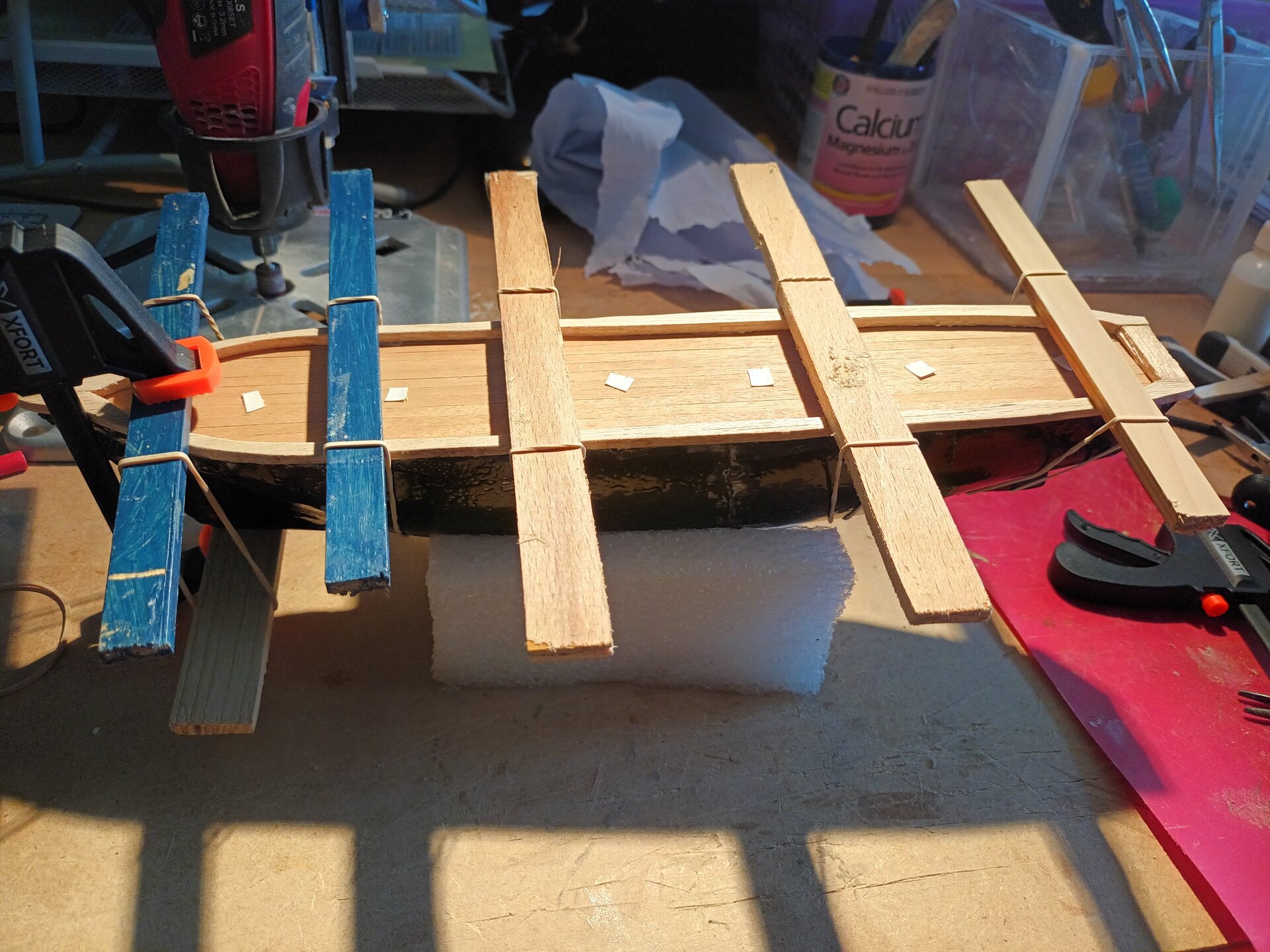

The pinewood deck was planked with thin strips of veneer. The veneer was left over from the previous build.

preparing the deck

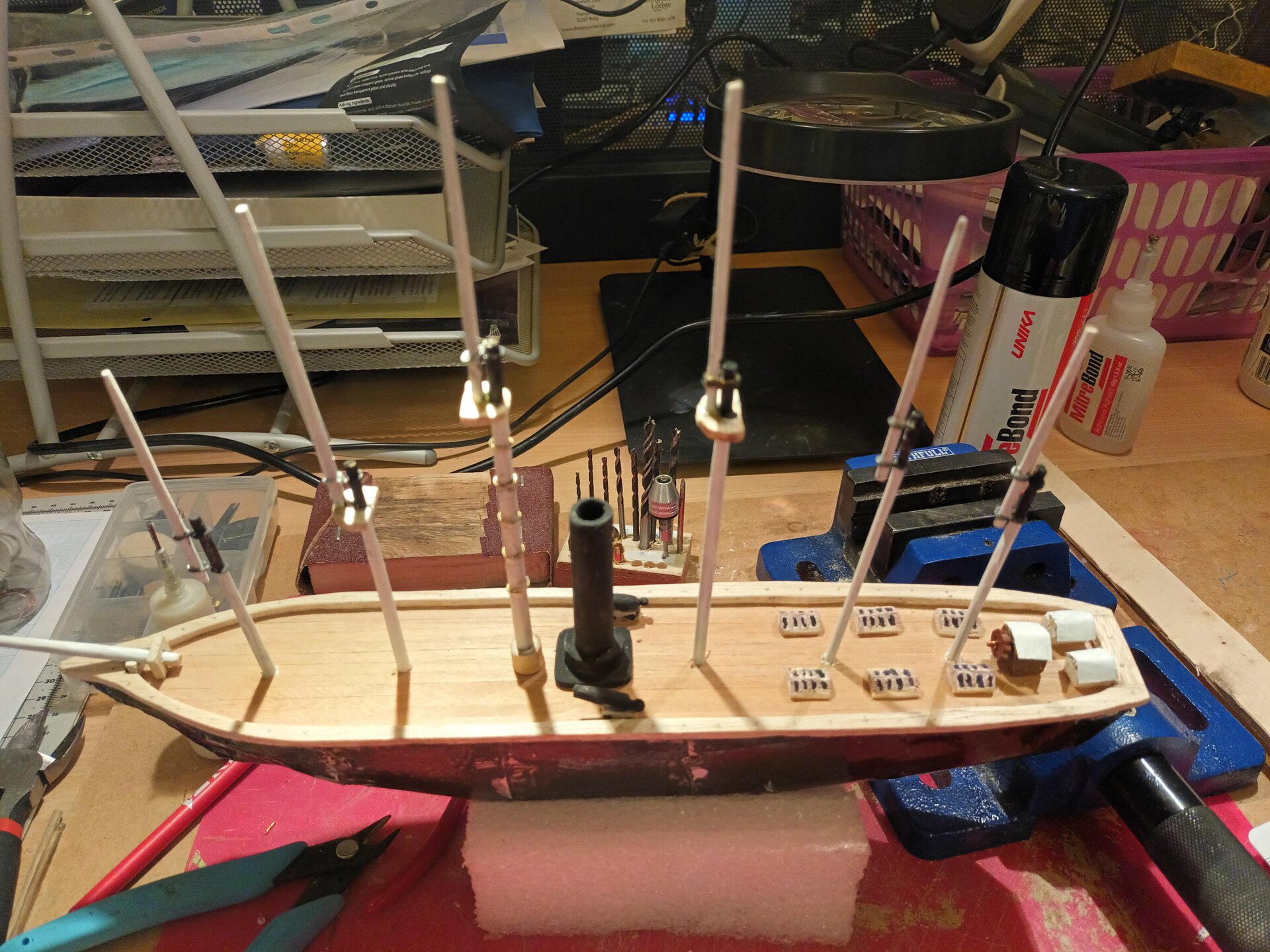

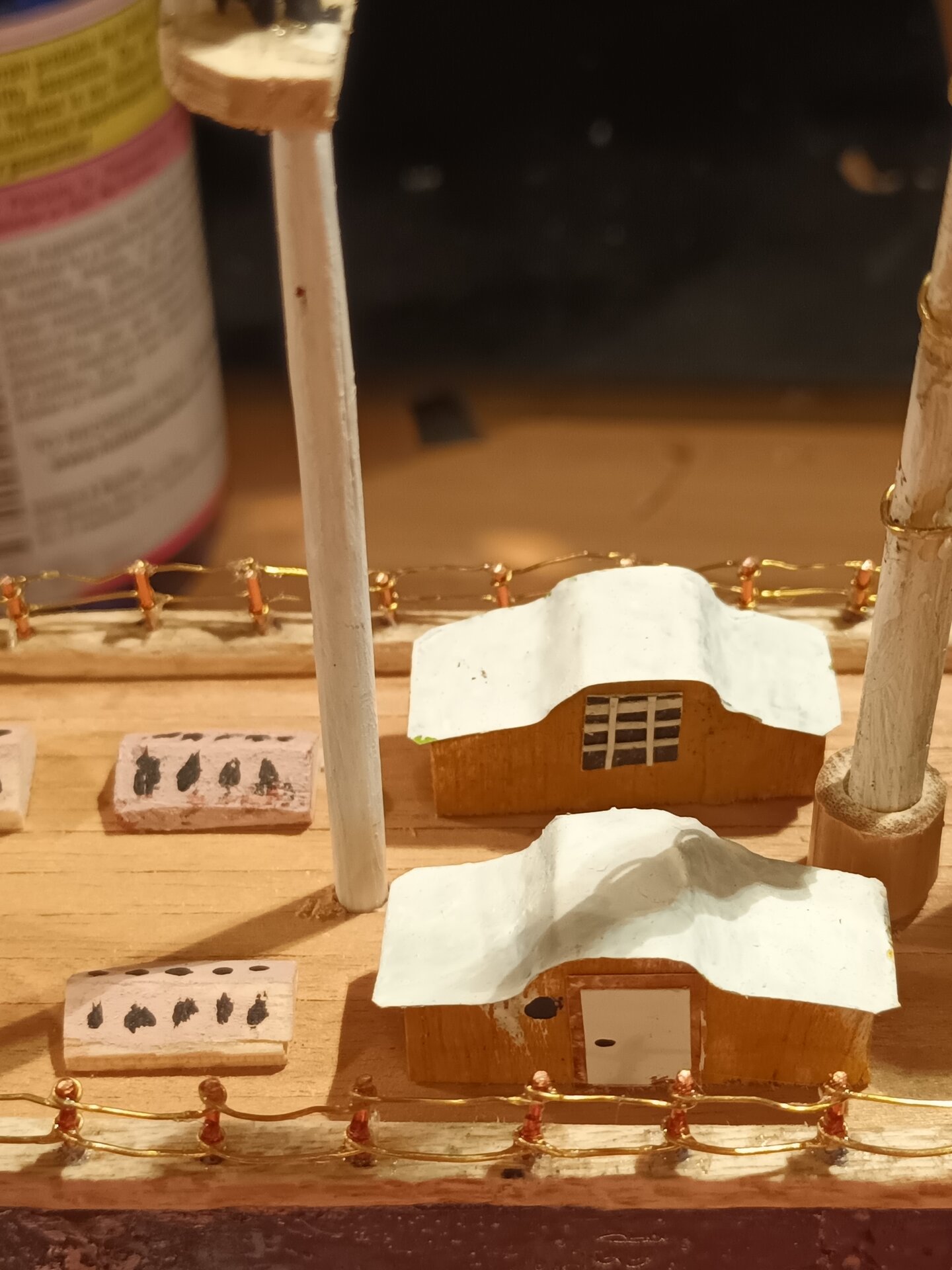

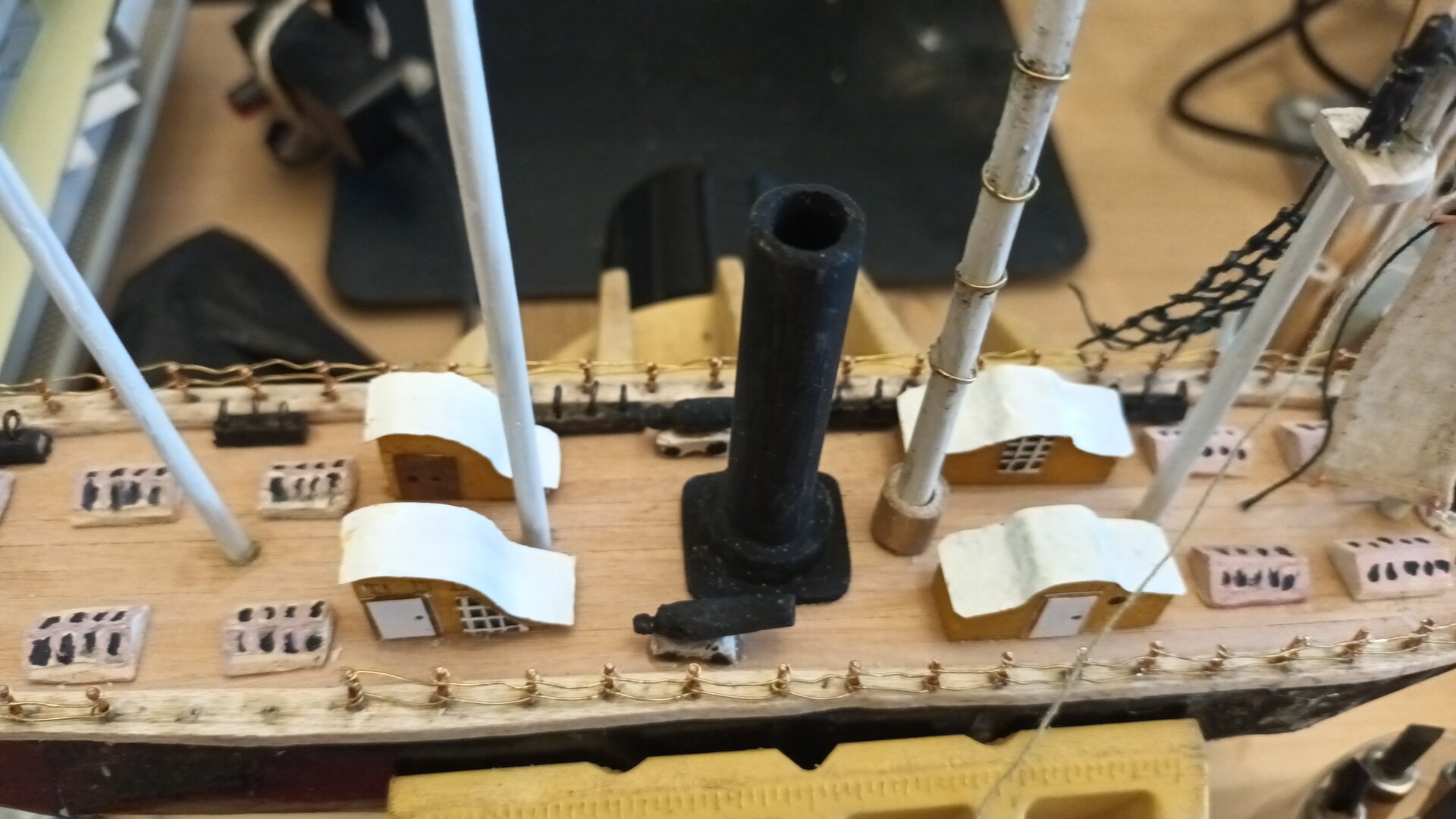

I decided to use softer wood to make the remaining hatches for better shaping of the items, and then carved the stairway ports from bayleaf wood found in the garden. The chimney was made from different sizes of bamboo fitting into each other to represent the bottom rim. Constructing the top and fitting the two sections of the mast introduced custom bending lots of tiny loops from copper wire. Just had enough space to fit in the cannons, also carved from scrap wood.

Repeating the process of the first mast, and carefully measuring the proportions of the other masts to the main mast allowed fitting of all the masts in place. However, first fitting the chimney did result in a grave error. The chimney should not be in the middle, but between the fourth and fifth mast.

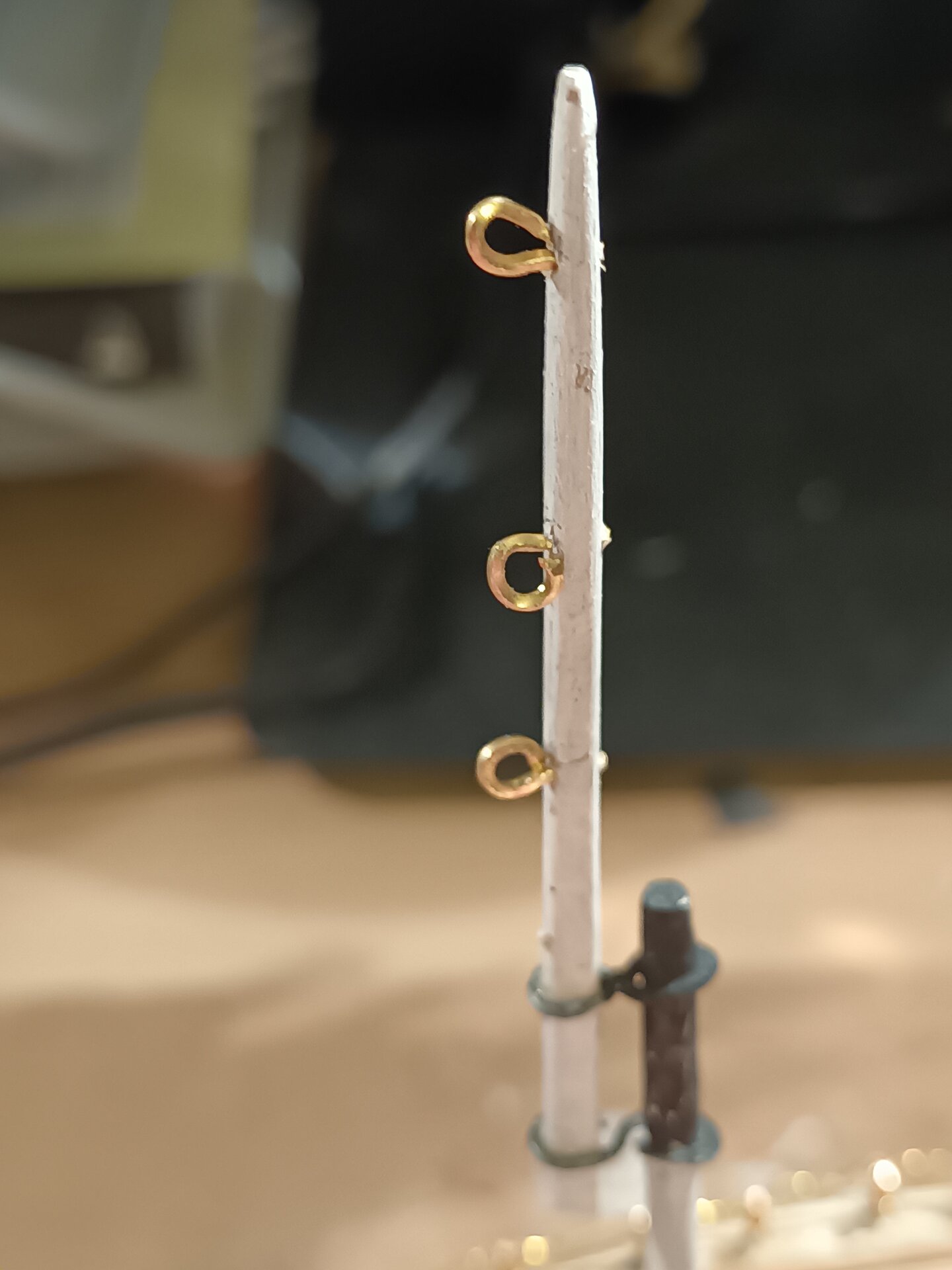

Multiple small copper and silver wire loops and eyes were made using nails in a piece of wood. The blocks were drilled and the eyes fitted to serve as rope ties for the rigging.

Each mast also had to have multiple eyes fitted for the rigging. Having the Gorch Fock kit handy helped to size and make the different fittings for the rigging on the deck, masts and tops. The pullies were made from 3 mm wood strips drilled to fit the lines through.

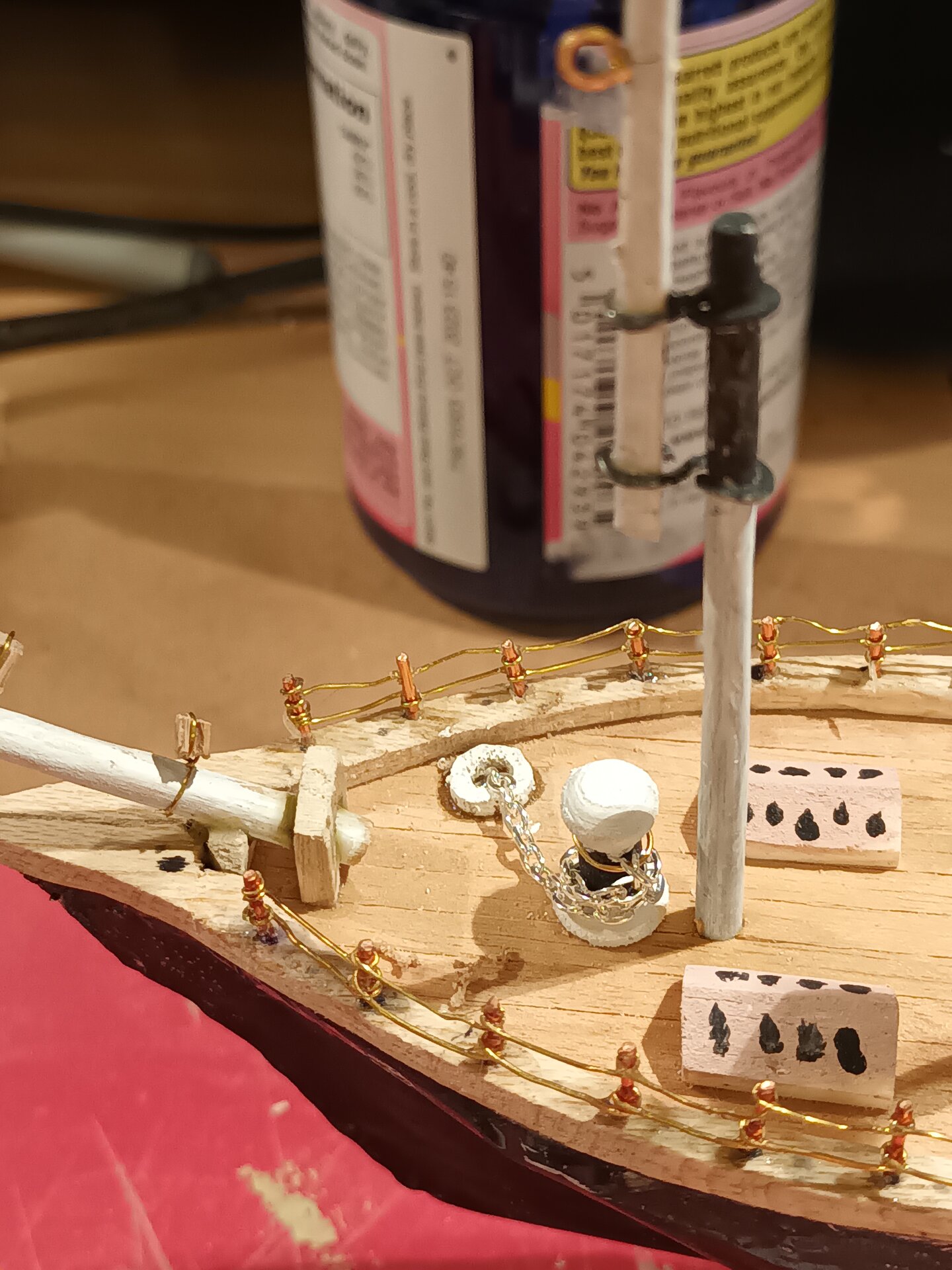

Had my first experience of turning the achor chain pulley from wood using a drill. The beer can tin could be used to form the roofs of all the cabins on the deck. It took we a while to work out how to make the railings for the boat. I did not manage to solder it, and finally managed to have small eyes in the wire for the copper posts, and used a bit of super glue to stick it together.

Many parts of the deck was a first for me to figure out how to approach it, discover or make tools to help with it, trial and error to experiment with different types of material and glue, navigate around my own limitations, and finally to get to something that is directionally right. Working with a 1:300 scale added to the challenge.

Completing the hull was a major achievement for me.

SS Great Britain Build Logs

-

SS Great Britain - Planning & Research

December 25, 2021 - Starting the ambitious SS Great Britain project with extensive research, reference gathering, and planning the build approach. -

SS Great Britain - Build Log: Hull Construction

February 10, 2022 - Hull construction phase - assembling the iron hull and adding structural details. -

Ss Great Britain - Build Log : Decking

March 13, 2022 - Deck construction and detailing work including planking, hatches, structural details and masts. -

Ss Great Britain - Build Log: Sails And Rigging

April 15, 2022 - Complex rigging work including six masts, sails, and associated lines and details. -

Ss Great Britain - Build Log: Decoration

May 15, 2022 - Decorative details, painting, and final detailing work before completion.

Have questions or feedback about this project? I'd love to hear from you.

Modelling4Comfort

Modelling4Comfort